Typical Problems Resolved by Commercial Refrigerator Repair Experts in Toronto

Typical Problems Resolved by Commercial Refrigerator Repair Experts in Toronto

Blog Article

Repairing Business Refrigeration Fixing: Methods for Quick and Effective Fixes

In the world of business refrigeration, the requirement for swift and specific troubleshooting techniques is critical. When a refrigeration system breakdowns, the effects can be disruptive and costly to service operations. Recognizing the usual problems that plague commercial refrigeration systems and having a toolkit of analysis strategies available can make all the difference in promptly recognizing and treating troubles. As we navigate with the complexities of fixing business refrigeration repair work, we will certainly discover the essential techniques for settling problems effectively, ensuring that companies can preserve ideal air conditioning performance and lessen downtime.

Typical Commercial Refrigeration Concerns

Commercial refrigeration systems commonly experience an array of operational problems that can disrupt their effectiveness and efficiency. One widespread issue is incorrect temperature control, which can lead to food perishing and waste if not promptly addressed.

Moreover, refrigerant leaks posture a considerable worry as they not just influence the air conditioning capability of the system yet also contribute to ecological harm. Detecting and repairing leakages without delay is vital to prevent additional damage and ensure compliance with laws. Furthermore, dirty condenser coils can hinder warm transfer, compeling the system to function harder and eat even more energy. Normal cleansing and upkeep can help avoid this issue and lengthen the life expectancy of the refrigeration system.

Diagnostic Tools and Techniques

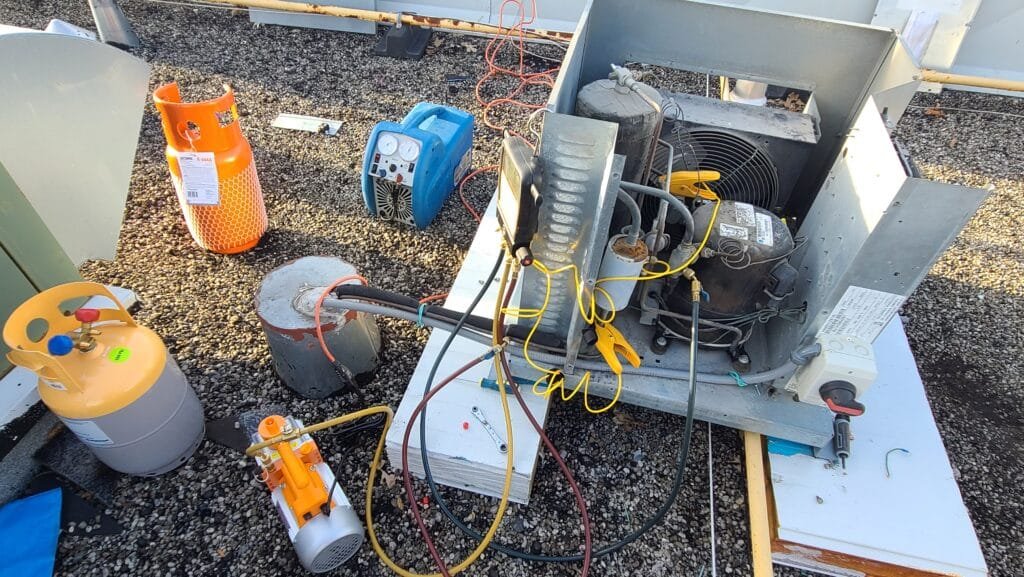

Efficient troubleshooting of industrial refrigeration systems counts greatly on making use of specialized analysis tools and techniques to determine and fix underlying problems effectively. One vital analysis device is the multimeter, which helps specialists gauge voltage, present, and resistance in numerous elements such as compressors, electric motors, and defrost heating systems. Thermostats are likewise essential for analyzing temperature differentials throughout the system to identify possible issues like cooling agent leaks or incorrect airflow. In addition, leakage detection devices like digital leakage detectors or ultraviolet color packages are important for locating cooling agent leakages that can cause system ineffectiveness.

Techniques such as pressure testing making use of manifold determines can figure out if the system has the right refrigerant fee and recognize any leaks. Visual inspections of elements for indicators of ice, deterioration, or wear build-up are additionally fundamental in identifying concerns. Information loggers can be used to keep track of system performance over time and identify patterns that might suggest recurring troubles. By incorporating these analysis devices and strategies, specialists can efficiently troubleshoot business refrigeration systems and supply quick and precise repair services, reducing downtime and guaranteeing ideal system performance.

Quick Repairs for Refrigeration Issues

When faced with refrigeration issues, technicians can carry out quick repairs to deal with usual issues promptly and successfully. If the refrigeration system is not cooling appropriately, inspecting and adjusting the thermostat setups might supply a fast remedy before even more extensive troubleshooting is needed. By implementing these fast repairs, service technicians can attend to common refrigeration troubles effectively my response and keep business refrigeration systems running efficiently.

Preventative Maintenance Tips

Applying a positive upkeep schedule is vital for ensuring the longevity and optimal efficiency of industrial refrigeration systems. Routine maintenance not only aids avoid pricey failures but likewise guarantees that the equipment runs effectively, conserving power and lowering overall operating prices. Here are some preventative upkeep ideas to maintain industrial refrigeration systems running smoothly:

Check and Replace Filters: Filthy filters can restrict air movement, making the system work more challenging and possibly creating damage. Examine and replace filters routinely to stop issues.

Inspect Seals and Gaskets: Leaking seals and gaskets can lead to temperature variations and energy wastefulness. Examining and replacing harmed seals can help preserve consistent temperature levels.

Expert Support and Provider

To keep the optimal performance attained through regular preventative upkeep, looking for specialist assistance and services for commercial refrigeration systems is necessary. Specialist service technicians possess the know-how and specialized expertise needed to diagnose and attend to intricate concerns efficiently. When facing tough refrigeration issues, counting on expert support can save both money and time over time.

Professional solutions use advantages such as access to advanced devices and devices, ensuring that repair work are performed effectively. Additionally, specialists are trained to comply with sector policies and security requirements, minimizing the danger of mishaps and making sure conformity with legal demands.

Verdict

In final thought, troubleshooting business refrigeration repair work calls for an organized method to recognizing common problems, utilizing analysis tools and his explanation methods, applying fast fixes, and focusing on preventative maintenance. Expert assistance and solutions might be necessary for more facility problems - commercial refrigeration repair. By following these strategies, companies can guarantee their refrigeration systems run efficiently and successfully, minimizing downtime and potential losses

Understanding the common concerns that plague commercial refrigeration systems and having a toolkit of analysis methods at your disposal can make all the difference in quickly identifying and correcting problems.Efficient troubleshooting of industrial refrigeration systems relies greatly on utilizing specialized analysis tools and techniques to determine and deal with underlying concerns effectively. By incorporating these diagnostic tools and techniques, technicians can effectively fix commercial refrigeration systems and provide fast and specific repairs, minimizing downtime and guaranteeing optimal system efficiency.

By implementing these fast repairs, service technicians can attend to common refrigeration problems successfully and maintain industrial refrigeration systems running smoothly.

Additionally, expert support can help expand the lifespan of business refrigeration systems by recognizing prospective issues prior to they rise.

Report this page